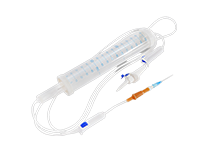

Dans le domaine médical, les seringues sont devenues une partie indispensable du moyen par lequel les médicaments pénètrent dans le corps du patient. Bien que les aiguilles d’injection soient souvent utilisées pour prélever du sang et injecter des médicaments, elles constituent un outil médical très utile. Cependant, il y a encore beaucoup de gens qui en ont très peur et développent une « phobie des aiguilles» qui commence à trembler face aux aiguilles. Cependant, la position de l'aiguille d'injection est inébranlable, car elle peut sauver des vies. Bien qu'il puisse sembler petit, il s'agit d'un processus complexe, alors quelles sont les étapes nécessaires pour produire le tube d'acier fin nécessaire à l'aiguille? En tant que professionnelFabricant de seringues jetablesNous l'expliquerons en détail ci - dessous.

Le matériau de l'aiguille est en acier inoxydable. Au début de la production, les travailleurs sont responsables de la transformation de blocs entiers d'acier inoxydable en structures tubulaires à l'aide de machines. Ensuite, pour s'assurer que l'ensemble du tube d'aiguille semble sans soudure, il est également nécessaire d'utiliser le soudage au laser pour souder tous les interstices afin d'obtenir un objet tubulaire standard très formel.

La dureté de l'acier inoxydable n'est pas suffisante pour atteindre la dureté requise pour la pointe de l'aiguille, de sorte que pour rendre le tube plus dur, les travailleurs de la production doivent effectuer de nombreux travaux à froid sur le tube, grâce à ce type de travail à froid, le tube peut également devenir plus mince. Ici, un tube d'acier qui sera transformé en aiguille d'injection est terminé.

Nous savons tous que le Haut de l'aiguille d'injection est pointu, donc la prochaine étape importante dans la production est de transformer l'extrémité arrondie du tube en une aiguille pointue sur le dessus. Tout d'abord, les tubes sont coupés le long d'une ligne avec un laminoir pour obtenir de petits tubes d'environ 5 cm de long. Les tubes coupés sont placés directement dans une boîte qui est vibrée par un dispositif pneumatique pour que tous les tubes soient bien alignés et que les travailleurs de la production puissent facilement les emballer et les envoyer à l'étape suivante du traitement.

Lorsque les travailleurs de la production emballent de petits tubes d'acier en balles, cela ne signifie pas qu'ils peuvent passer à l'étape suivante. En effet, à ce stade, les tubes sont sélectionnés au hasard dans chaque paquet de tubes pour inspection à l'aide d'un appareil de mesure laser de pointe afin de mesurer le diamètre extérieur du tube de la broche, qui doit être maintenu à environ 2 mm. Les tubes qui ont passé avec succès le test sont ensuite alignés et collés à l'extérieur des tubes avec une machine afin que tous les tubes soient complètement collés ensemble pour un traitement ultérieur.

Les ouvriers de production coupent les longs tubes en bandes d'environ 12 cm, chacune d'environ 100 tubes. L'alumine est ensuite pulvérisée à l'extrémité de la bande pour nettoyer la surface du tube et faciliter son usinage. Une fois le tube complètement nettoyé, il est placé sur une machine appelée pince abrasive. Après le démarrage de la machine, le liquide abrasif à l'intérieur commencera à rincer l'embouchure du tube, puis la meule à l'intérieur affûtera grossièrement l'embouchure du tube.

Après cela, en raison de la rotation de l'outil de meulage, le tube d'acier sera rincé et aiguisé à nouveau à plusieurs reprises et la meule ajustera l'angle à temps en fonction de la taille du tube d'aiguille. La pointe de l'aiguille devient alors plus tranchante et a l'apparence d'une aiguille d'injection que nous voyons normalement.

Ce qui précède concerne le traitement de l'aiguille d'injection, dans l'espoir de vous aider dans votre achat.